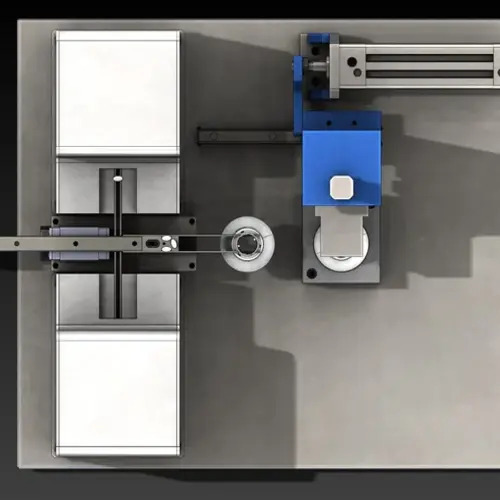

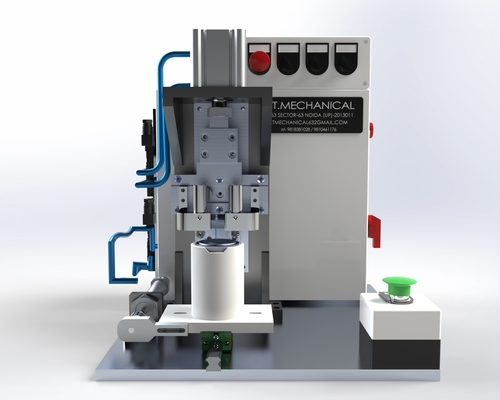

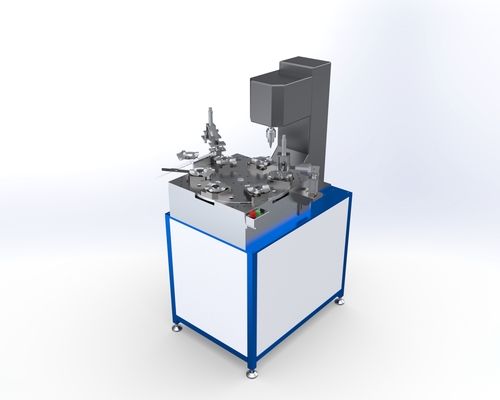

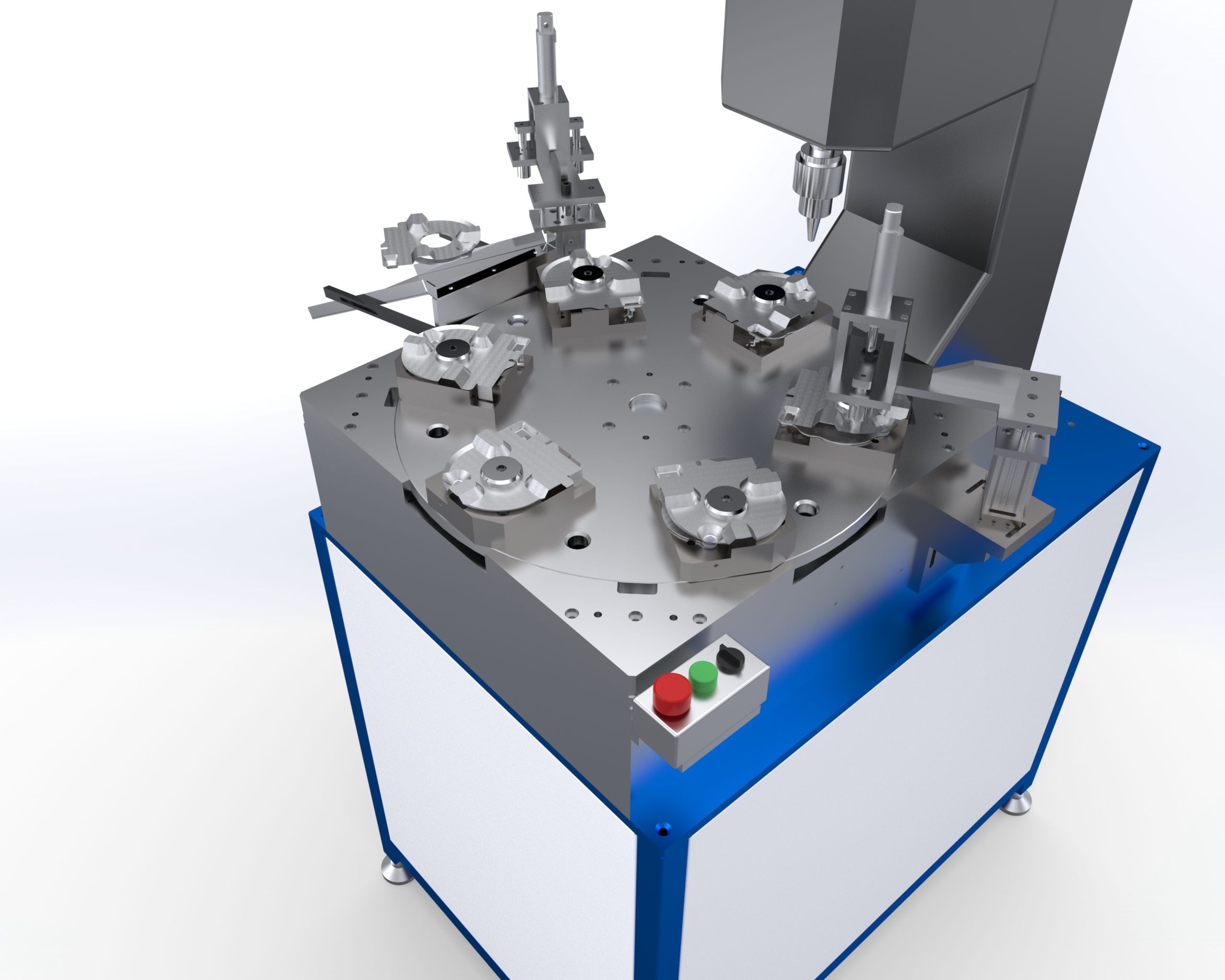

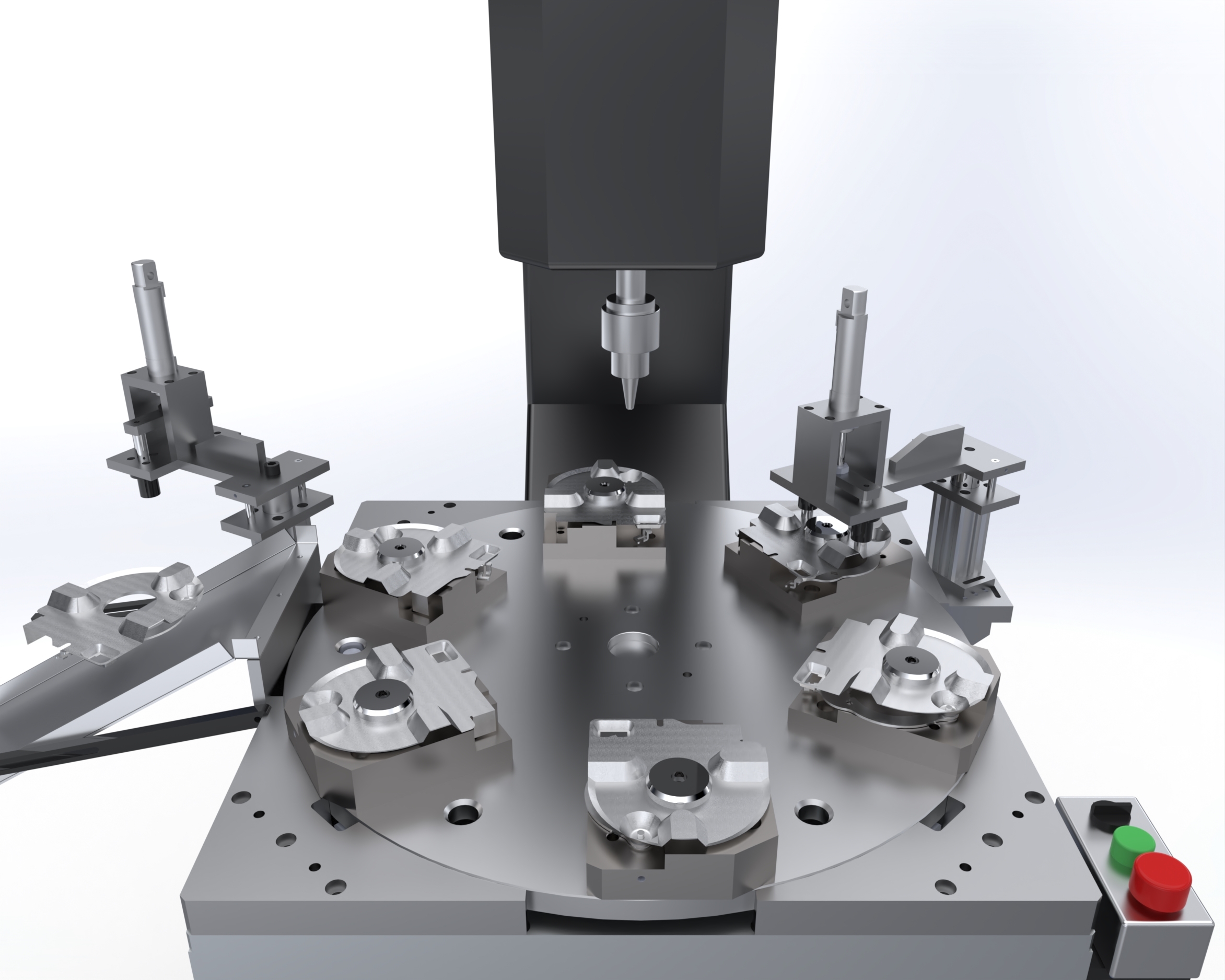

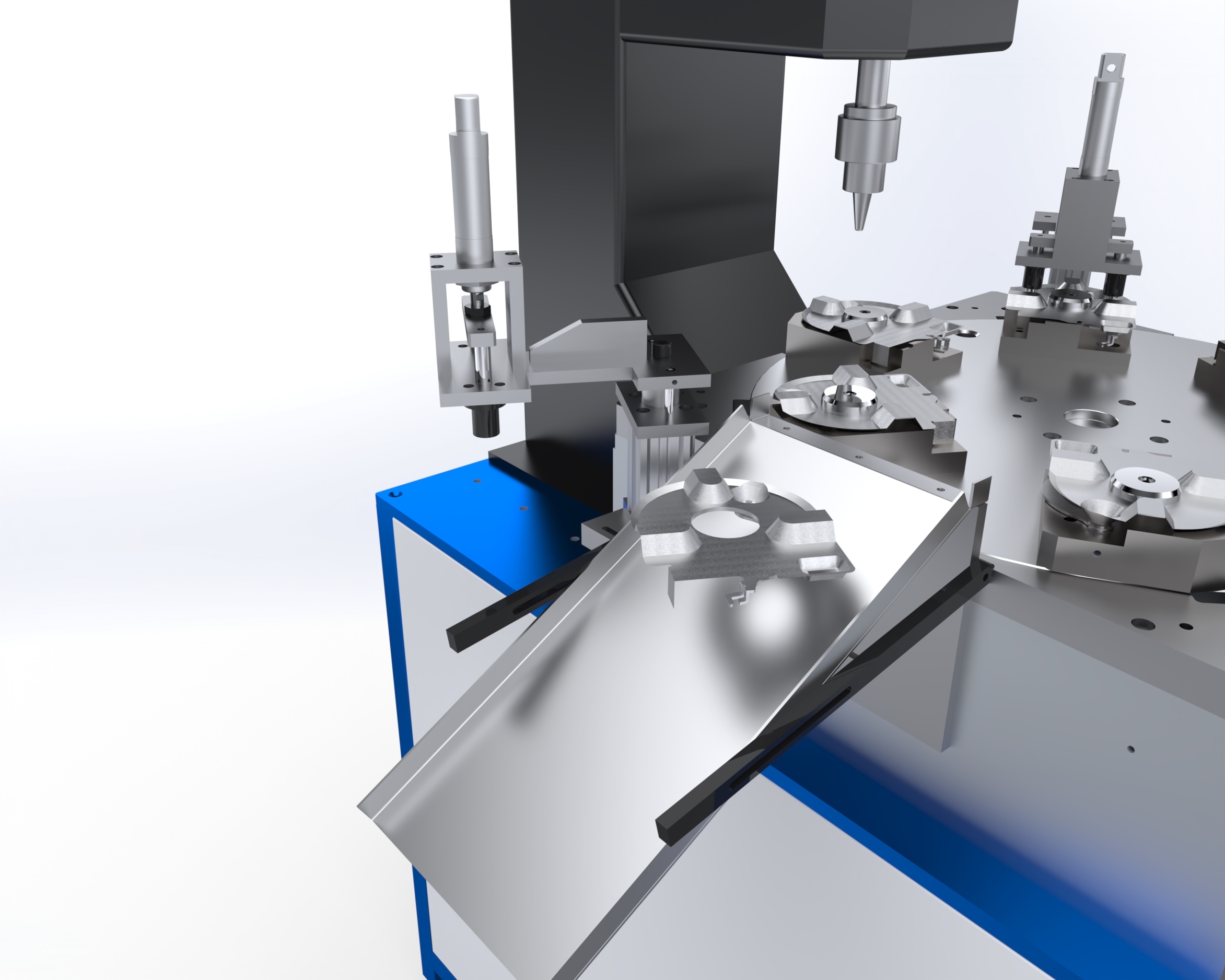

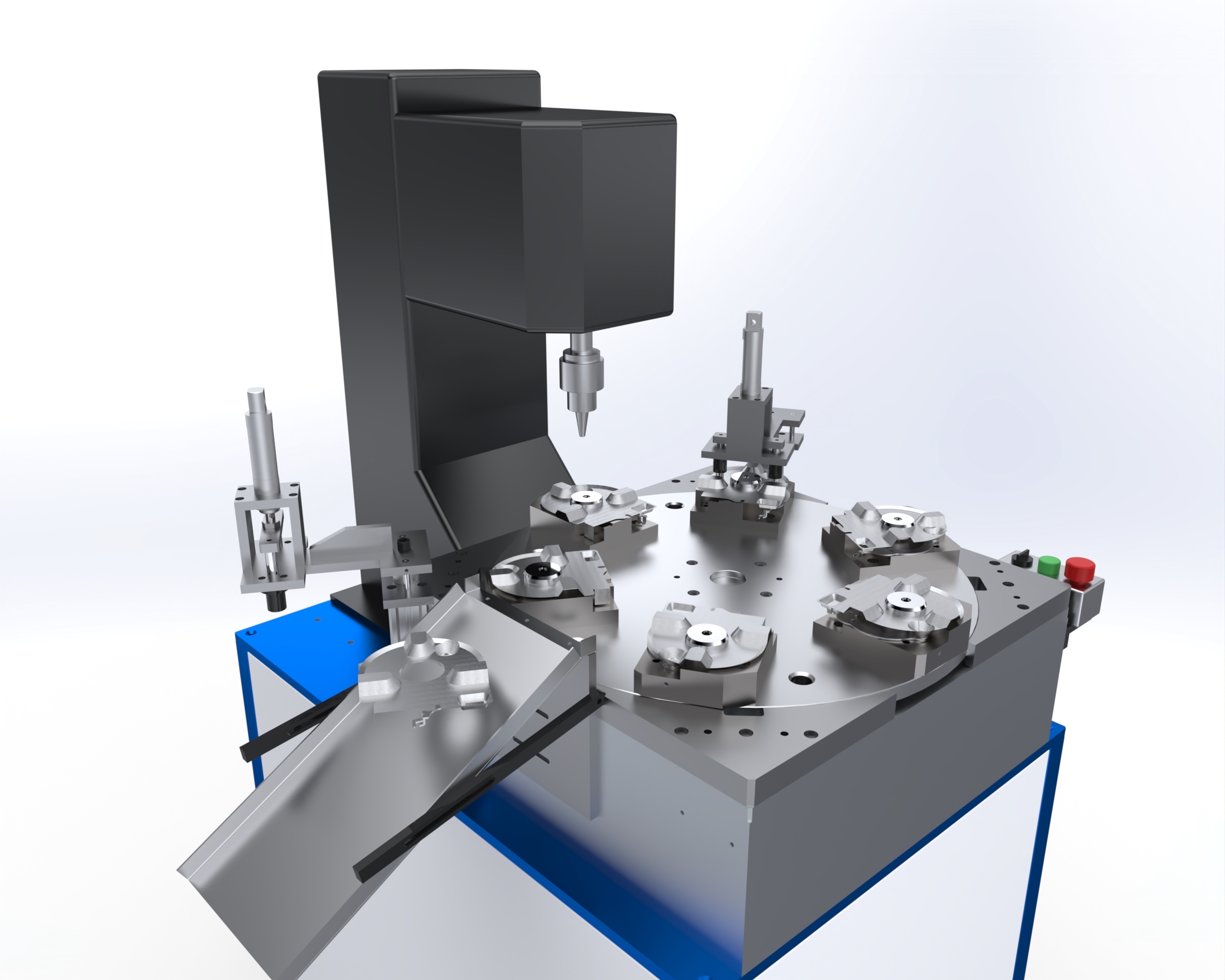

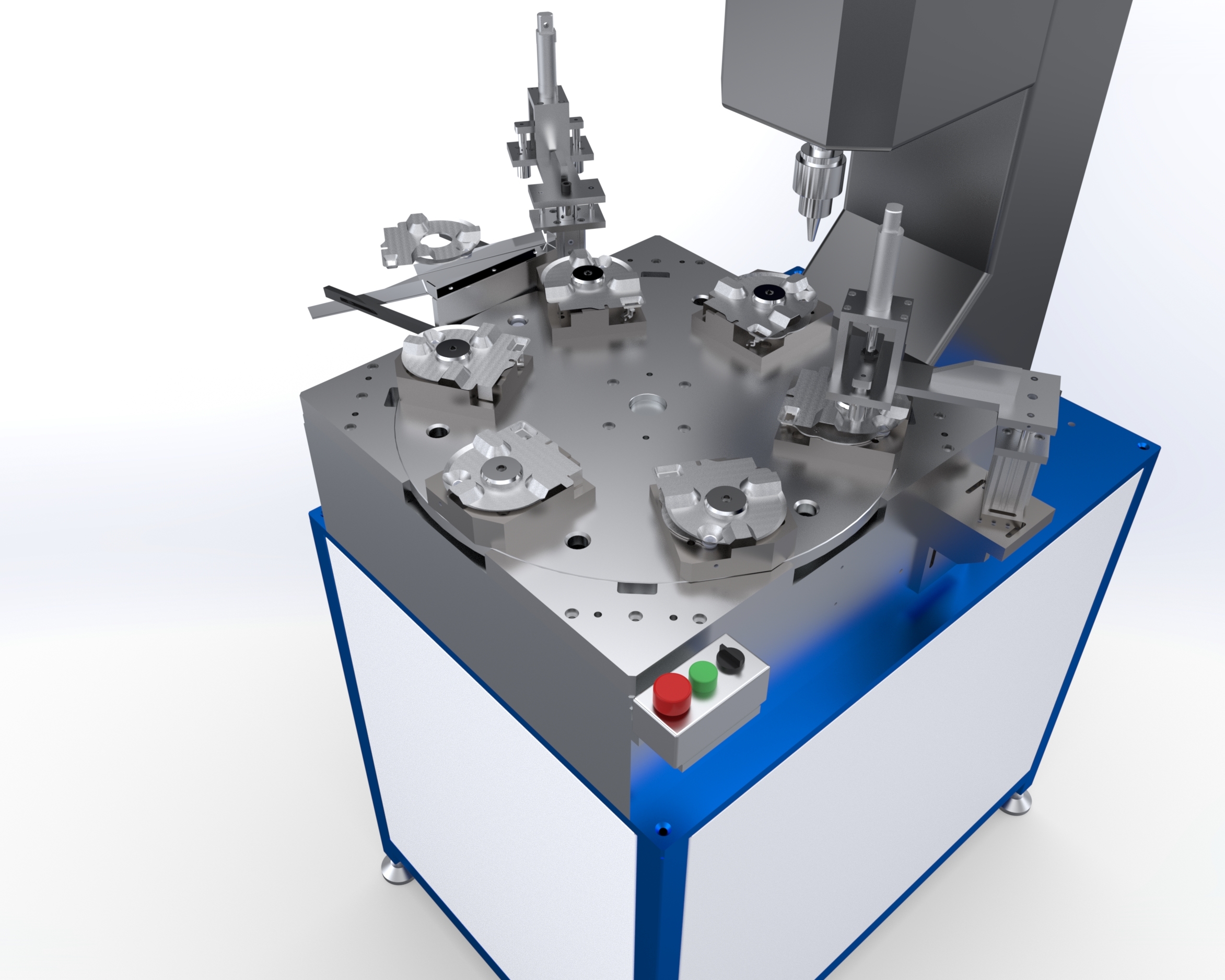

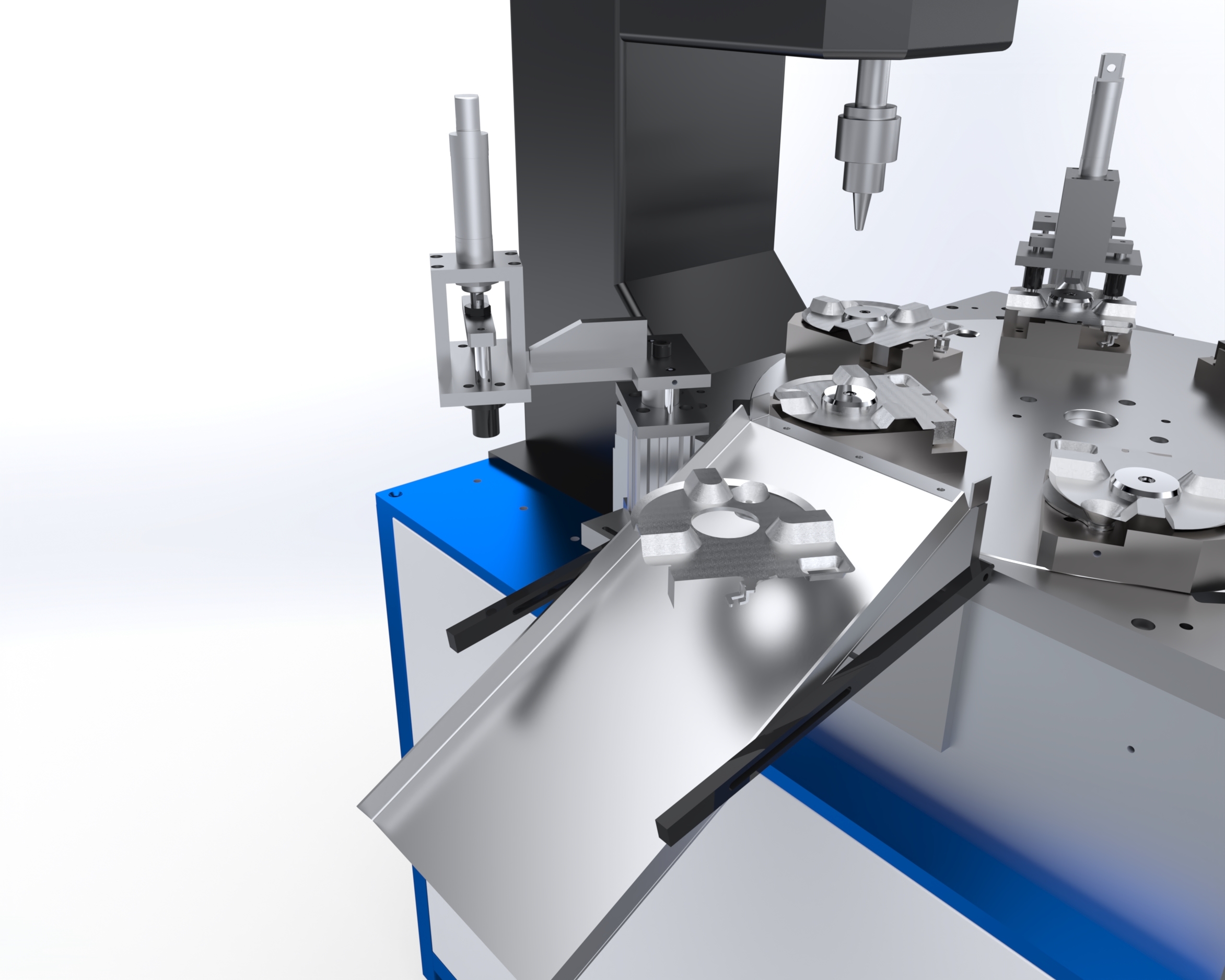

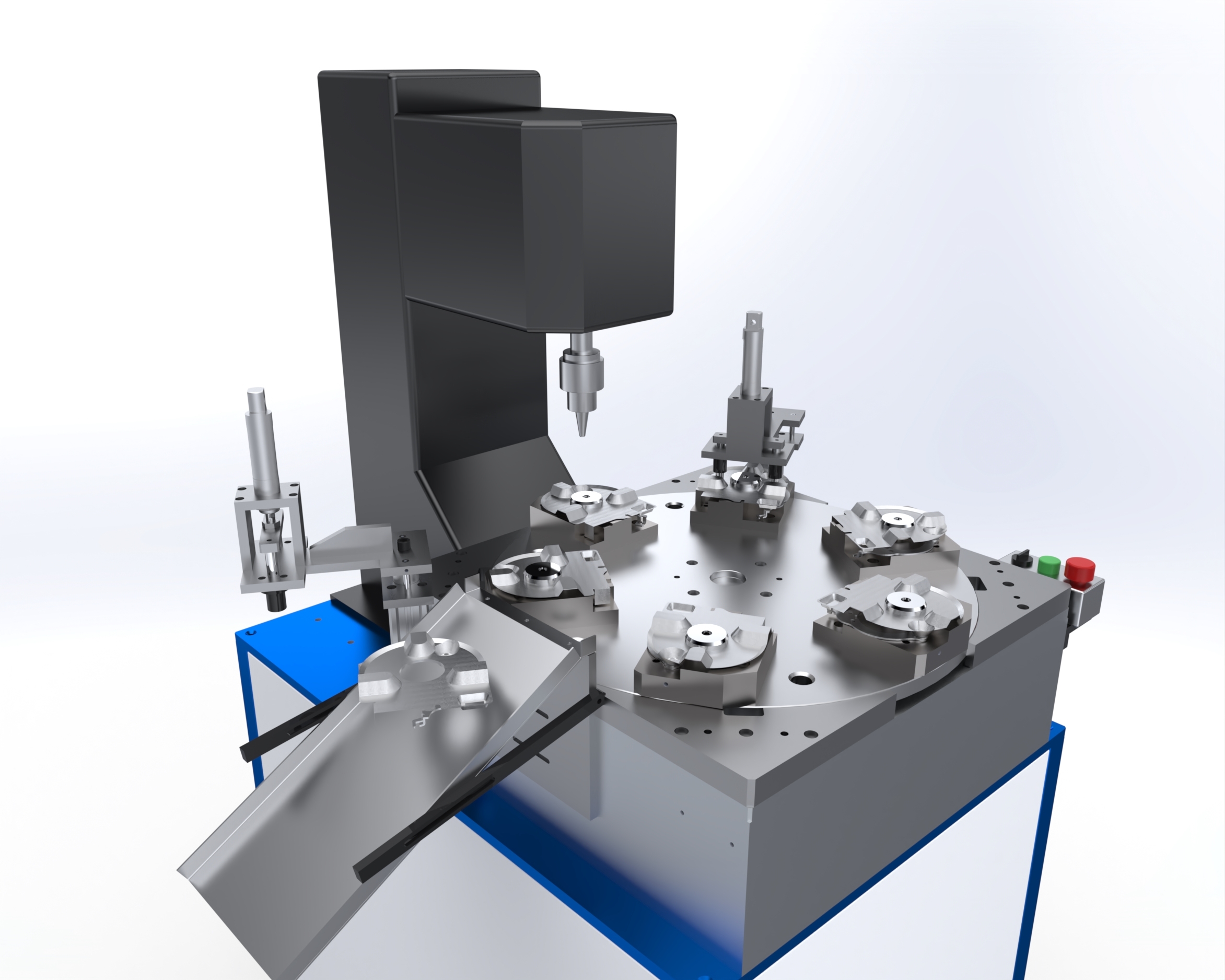

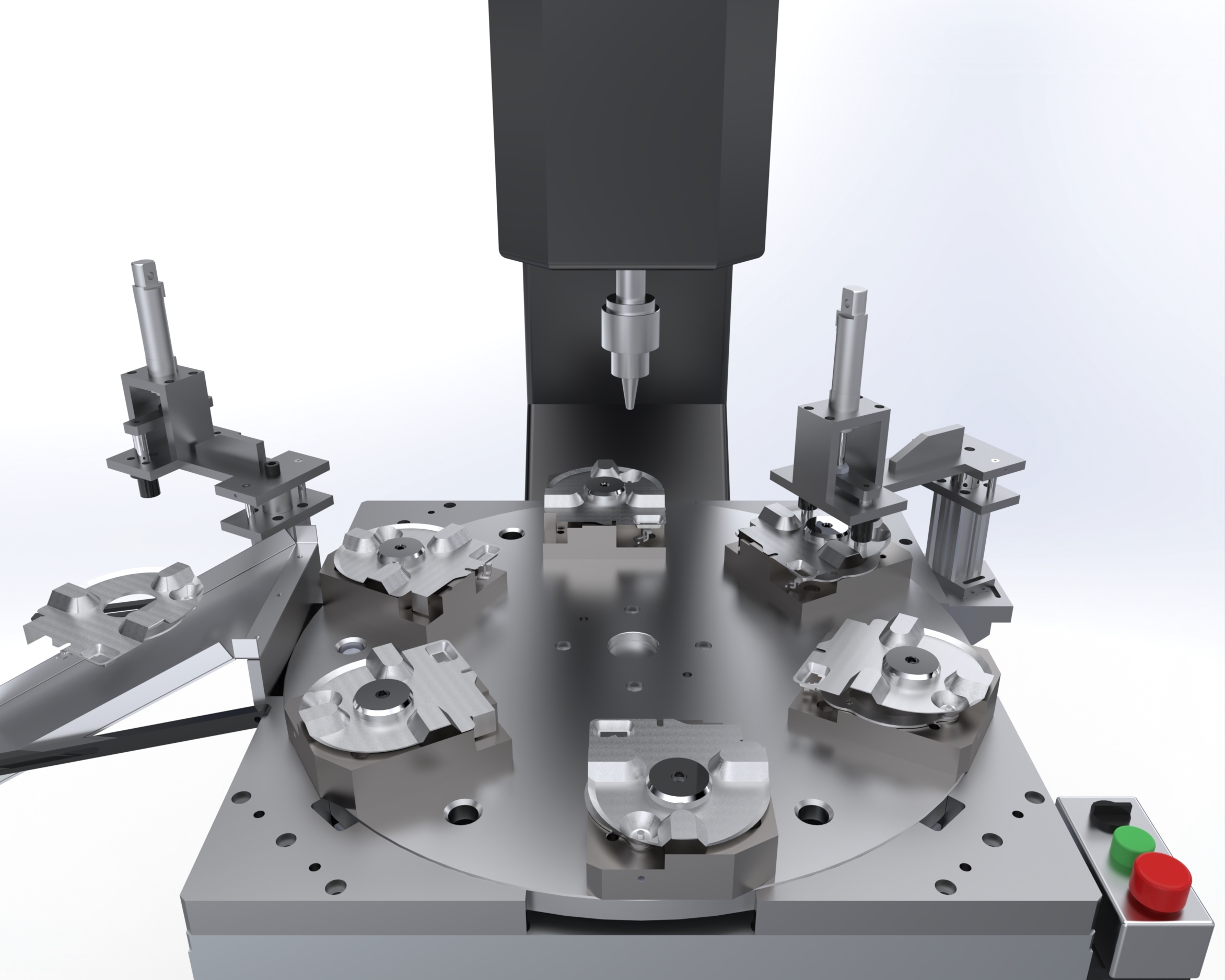

Automatic Orbital Riveting Machine

Price 250000 INR/ Piece

Automatic Orbital Riveting Machine Specification

- Shape

- Rectangular Base, Cylindrical Head

- Diameter

- Suitable for rivets 2 mm 12 mm

- Phase

- Single Phase/Three Phase

- Torque

- Adjustable up to 100 Nm

- Product Type

- Automatic Orbital Riveting Machine

- General Use

- Riveting/Assembly of automotive, electronic, hardware, and industrial components

- Material

- Mild Steel (frame), Hardened Tool Steel (ram)

- Type

- Orbital Riveting Machine

- Capacity

- Up to 20,000 rivets/hour (depending on model & material)

- Weight (kg)

- 320 kg

- Computerized

- Yes

- Automatic

- Yes

- Touch Screen

- Yes

- Control System

- PLC Based

- Surface Treatment

- Powder Coated

- QC System

- Integrated quality monitoring with error alert

- Tolerance

- 0.02 mm

- Drawing

- Available upon request

- Voltage

- 220V/380V, 50/60Hz

- Dimension (L*W*H)

- 1200 mm x 800 mm x 1700 mm

- Feature

- Low noise operation, high precision, low maintenance, energy-efficient

- Color

- Industrial Blue/Custom

- Noise Level

- < 70 dB(A)

- Max Force

- Up to 25 kN

- Operator Level

- Semi-skilled operator

- Riveting Stroke

- Up to 50 mm adjustable

- Safety Features

- Light curtain, emergency stop, two-hand control

- Lubrication

- Centralized automatic lubrication system

- Power Consumption

- 1.5 kW

- Import/Export Certification

- CE Marked, ISO 9001:2015 compliant

- Tool Holder

- Quick change modular system

- Display

- 7-inch HMI color touchscreen

- Cycle Time

- 0.7 - 1.5 seconds per cycle

- Rivet Head Type

- Dome, Countersunk, Flat, Custom profiles

- Production Rate

- Up to 1800 pieces/hour (operator dependent)

- Air Supply

- 5-7 bar (if pneumatic-assist model)

Automatic Orbital Riveting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Noida

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 20 Days

- Main Domestic Market

- All India

About Automatic Orbital Riveting Machine

Comprehensive Application and Operation Overview

The Automatic Orbital Riveting Machine is widely used by automotive, electronics, hardware, and industrial component manufacturers across India and global export markets. It employs a semi-skilled operator, facilitating easy application via a PLC-based control system and a 7-inch touchscreen display. Its versatile tooling allows usage with dome, countersunk, flat, and custom rivet profiles. Designed for reliability and high precision, it seamlessly integrates into any assembly line, optimizing riveting and production operations efficiently.

Order Fulfillment, Export Logistics, and Payment Information

Order processing for the Automatic Orbital Riveting Machine is swift, ensuring minimal delivery lead time. Shipments typically depart from major Indian FOB ports, leveraging the company's strong export market presence. Upon receipt of a purchase order, the machine is packed and dispatched efficiently. Payment terms are flexible, available through bank wire transfer and LC (Letter of Credit), making procurement seamless for both national and international buyers eager to add this remarkable system to their assembly processes.

FAQ's of Automatic Orbital Riveting Machine:

Q: How does the Automatic Orbital Riveting Machine enhance production efficiency?

A: The machine significantly boosts production efficiency with a cycle time of 0.7-1.5 seconds, achieving up to 1800 pieces per hour, depending on the operator and material. Its computerized, PLC-based system streamlines operation and reduces downtime.Q: What safety features are included with the riveting machine?

A: This machine is equipped with several safety features, including a light curtain, emergency stop button, and two-hand control. These features ensure operator safety during use and comply with CE and ISO 9001:2015 standards.Q: Where can the Orbital Riveting Machine be used?

A: The machine is notably versatile, suitable for the assembly of automotive, electronic, hardware, and general industrial components, making it ideal for various manufacturing environments.Q: What is the process for changing tool profiles on the machine?

A: Thanks to its quick-change modular tool holder system, operators can easily switch between dome, countersunk, flat, or custom rivet head types, adapting to distinct application requirements within minutes.Q: When is the Automatic Orbital Riveting Machine available for export?

A: Following placement of a purchase order, order processing begins immediately. Delivery schedules are communicated, and shipments are organized from key FOB ports in India to destinations worldwide.Q: What are the benefits of centralized automatic lubrication?

A: Centralized automatic lubrication ensures consistent performance, reduces wear, and minimizes maintenance needs, resulting in longer machine life and uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Machine Category

Automatic LED Bulb Assembly Machine

Price 1300000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

General Use : Industrial

Feature : Stable Operation, High Performance, ECO Friendly, Low Noise, High Efficiency

Computerized : No

Automatic Led Bulb Production Machine

Price 190000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : PLC Control

General Use : Industrial

Feature : ECO Friendly

Computerized : No

LED Bulb Cap Crimping Machines

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : PLC Control

General Use : Industrial

Feature : ECO Friendly

Computerized : No

LED Bulb Notching And Bending Machine

Price 95000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

General Use : Industrial

Feature : ECO Friendly

Computerized : No

|

M/S K.T.MECHANICAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry