LED Bulb Assembly Machine

Price 1200000.0 INR/ Number

LED Bulb Assembly Machine Specification

- Product Type

- Assembly Machine

- General Use

- LED Bulb Assembly

- Material

- Aluminum Alloy

- Type

- Other

- Capacity

- 3200 Pcs/hr

- Weight (kg)

- 700 Kilograms (kg)

- Computerized

- Yes

- Automatic

- No

- Touch Screen

- Yes

- Control System

- PLC Control

- Surface Treatment

- Anodize

- Drawing

- 3D

- Dimension (L*W*H)

- Millimeter (mm)

- Color

- Blue & White

- Warranty

- 1 Year

LED Bulb Assembly Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

- Sample Available

- No

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About LED Bulb Assembly Machine

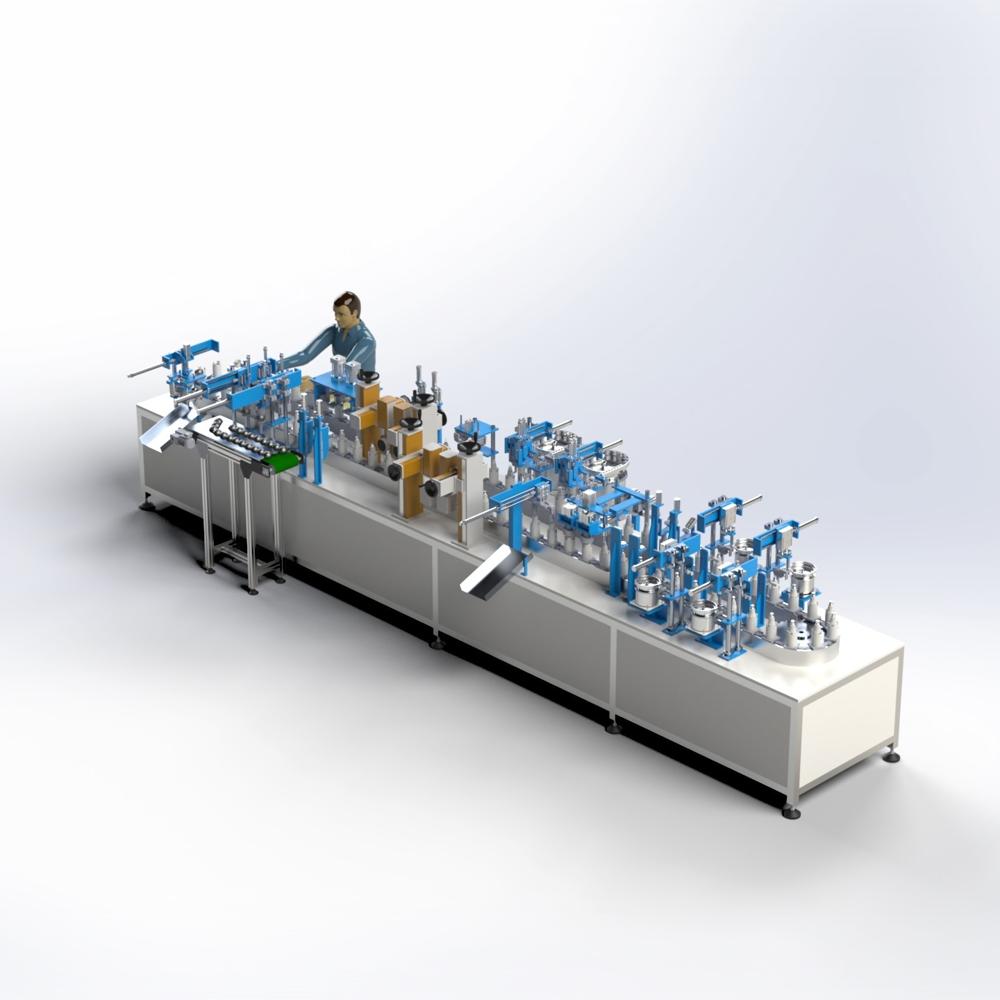

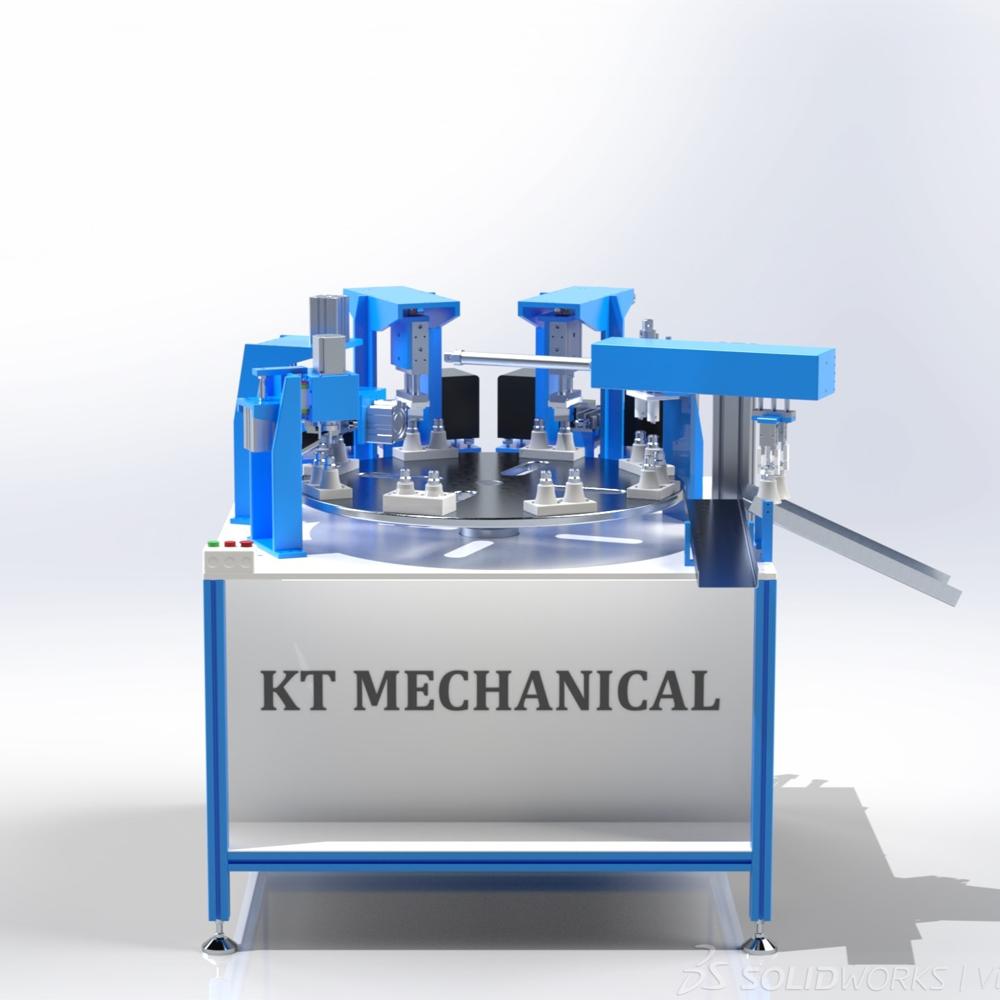

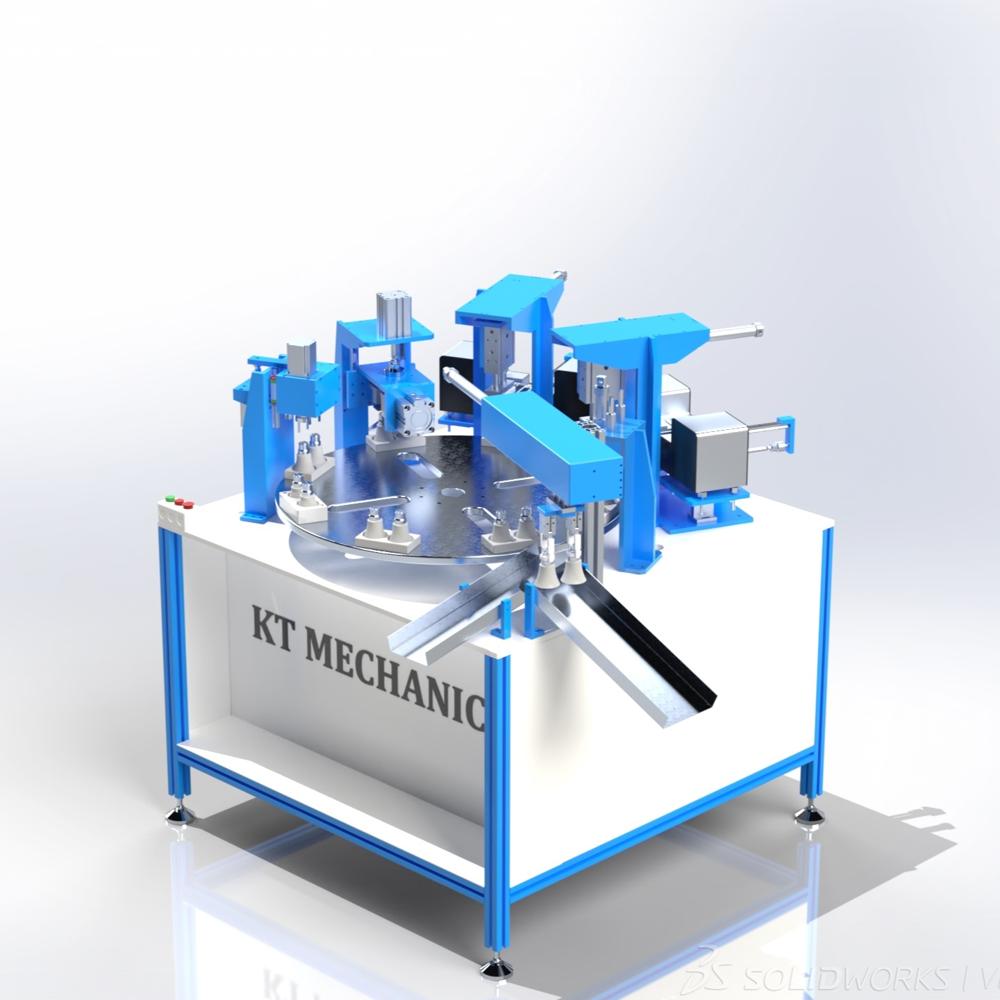

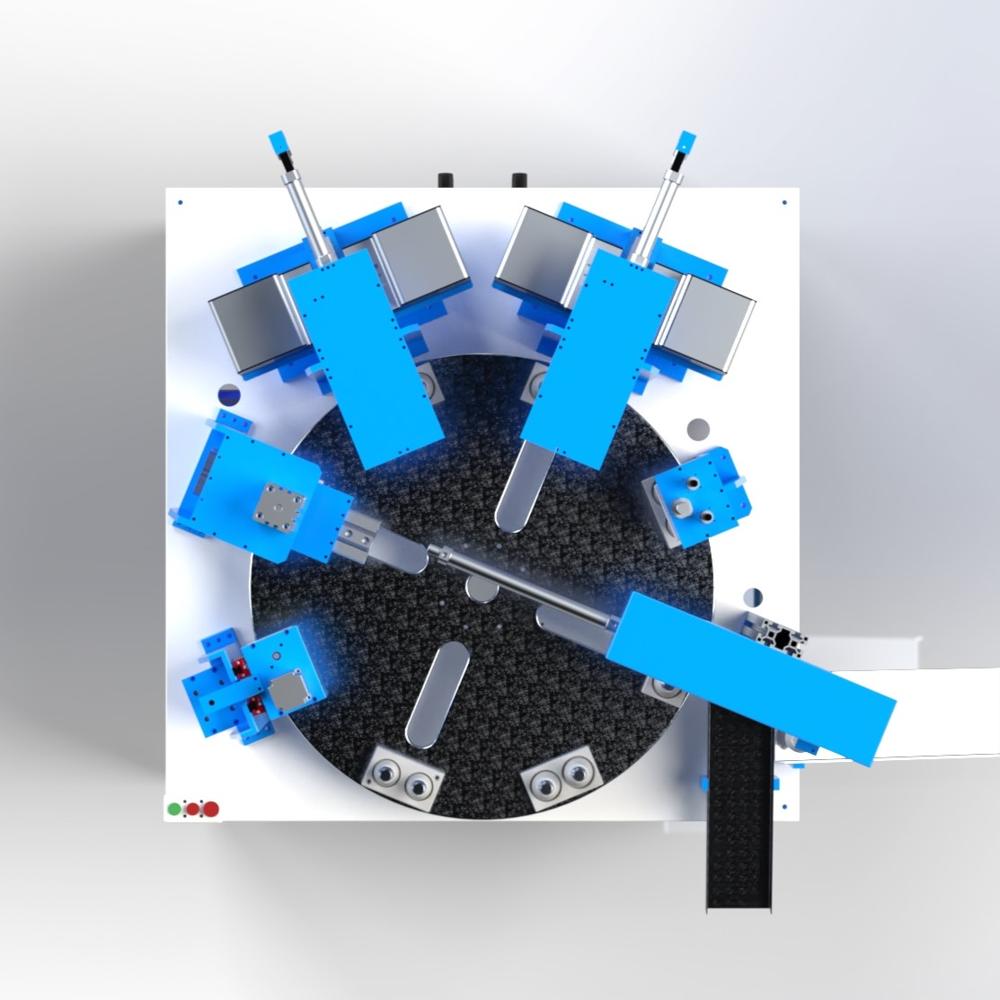

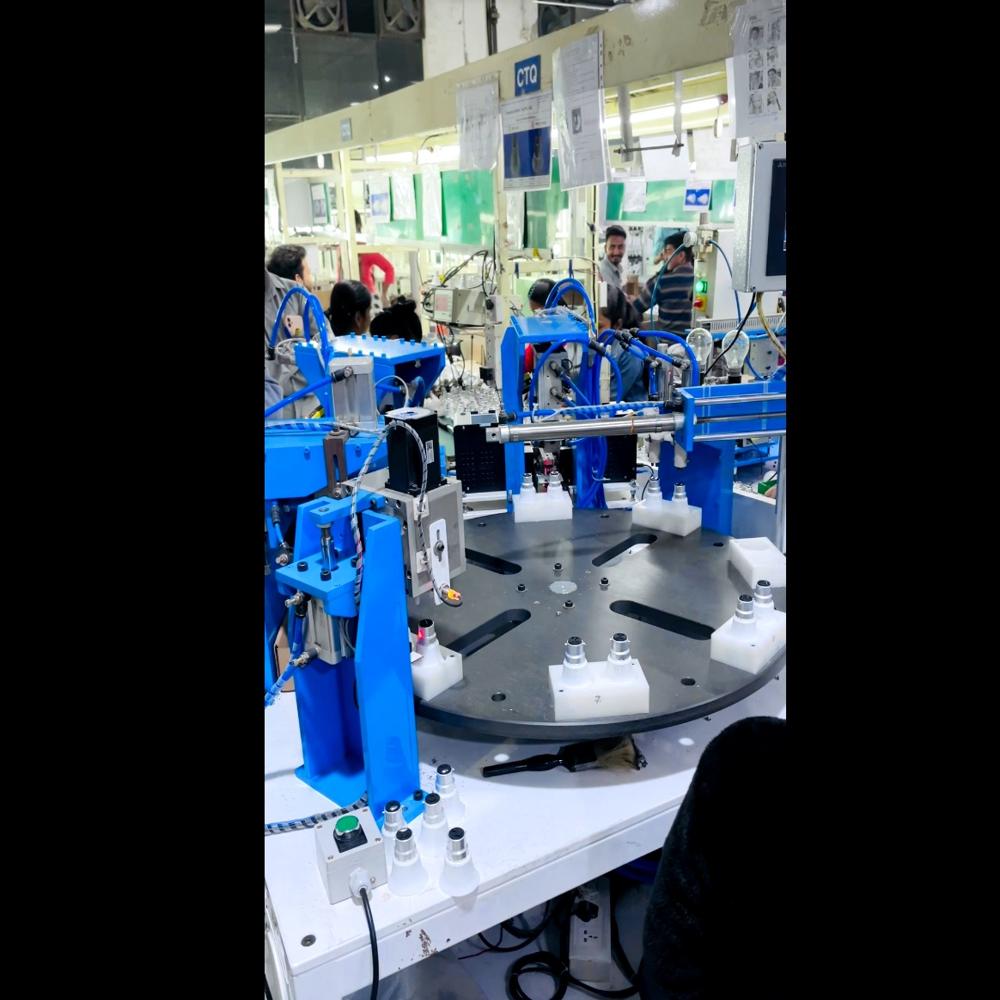

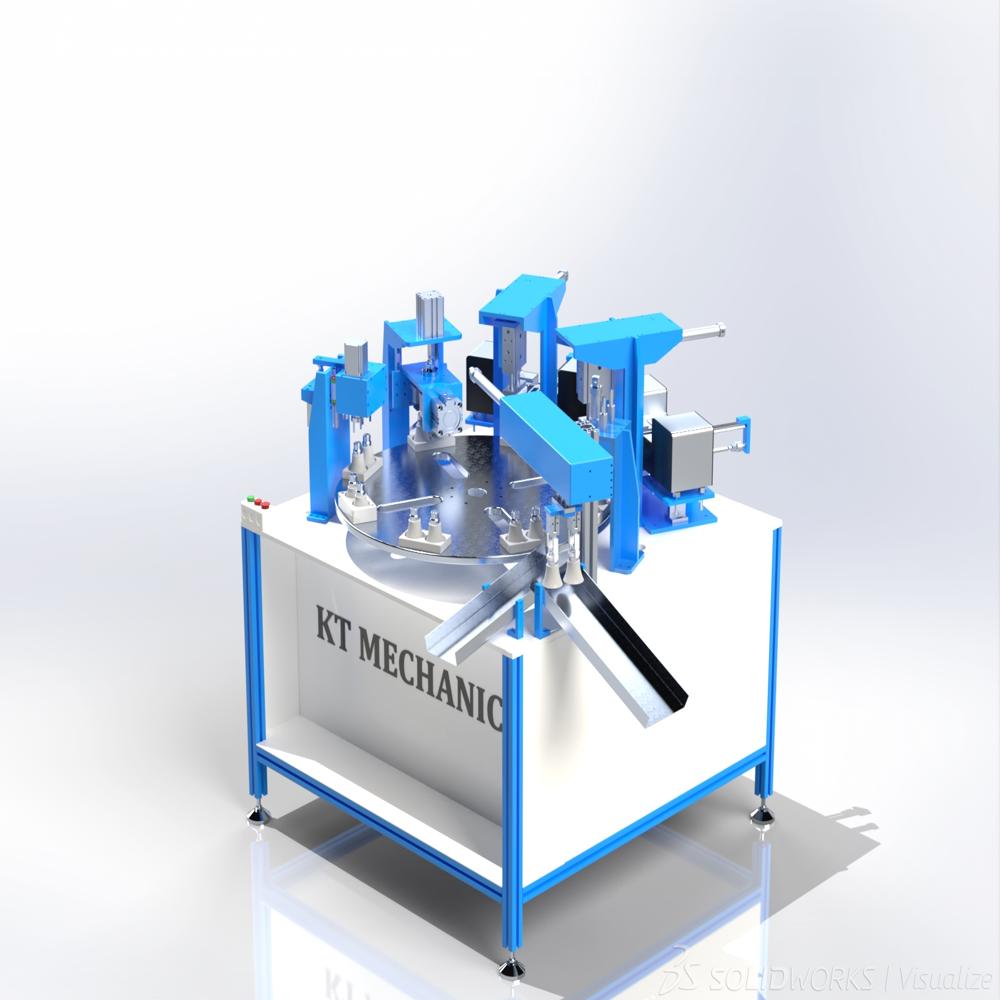

We offer a high-precision Rotary LED Bulb Assembly & Testing Machine designed for the fast and consistent assembly of LED bulb housings with B22 caps. The machine features manual loading and automated multi-station operation on a cam-based rotary indexing platform, ensuring efficient assembly and real-time quality testing of two bulbs per cycle.

Key Features:-

Cam Indexer-Based Rotary Table

-

Dual-Part Fixture for Higher Throughput

-

Automatic B22 Cap Alignment via Pin Guidance

-

Wire Cutting & Bending System

-

Eyelet Insertion Units for Both Bulbs

-

Integrated Power Meter Testing for Both Bulbs

-

Automatic OK/NG Ejection via Separate Chutes

-

Compact Design with PLC + HMI Control

-

Low Maintenance & Operator-Friendly

-

Manual Loading: Operator loads two LED housings (with B22 caps) into the fixture.

-

Cap Orientation: The machine aligns the cap using pin guidance for accurate positioning.

-

Wire Cutting & Bending: Cuts and bends wires coming from the B22 cap.

-

Eyelet Fixing Unit 1: Inserts eyelet into the first housing's B22 cap.

-

Eyelet Fixing Unit 2: Inserts eyelet into the second housing in the same fixture.

-

Testing Station: Checks both bulbs for electrical parameters using power meters. Sends OK/NG signal to PLC.

-

Auto Ejection: OK bulbs move to conveyor via OK chute, NG bulbs to bin via separate chute.

This machine is ideal for LED bulb manufacturers seeking to automate their production line, improve quality control, and reduce manual workload.

Customization Available

Made in India

Backed by After-Sales Support

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LED Bulb Assembly Machine Category

Pick and Place for Power Press

Price 800000.0 INR / Unit

Minimum Order Quantity : 1 Number

Feature : High Efficiency, Simple Control, Stable Operation, High Performance, ECO Friendly, Low Noise

Type : Milling

Control System : PLC Control

Material : Aluminum Alloy

|

M/S K.T.MECHANICAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry