Pick and Place for Power Press

Price 800000.0 INR/ Unit

Pick and Place for Power Press Specification

- Diameter

- 2 Meter (m)

- Product Type

- Automatic Transfer System for Power Press

- Material

- Aluminum Alloy

- Type

- Milling

- Capacity

- 800 Pcs/hr

- Weight (kg)

- 50 Kilograms (kg)

- Computerized

- Yes

- Automatic

- Yes

- Touch Screen

- Yes

- Control System

- PLC Control

- Surface Treatment

- Anodize

- QC System

- Yes

- Drawing

- 3D

- Dimension (L*W*H)

- 0

- Feature

- High Efficiency, Simple Control, Stable Operation, High Performance, ECO Friendly, Low Noise

- Color

- Grey

- Warranty

- 1 year

Pick and Place for Power Press Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Noida

- Supply Ability

- 5 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

About Pick and Place for Power Press

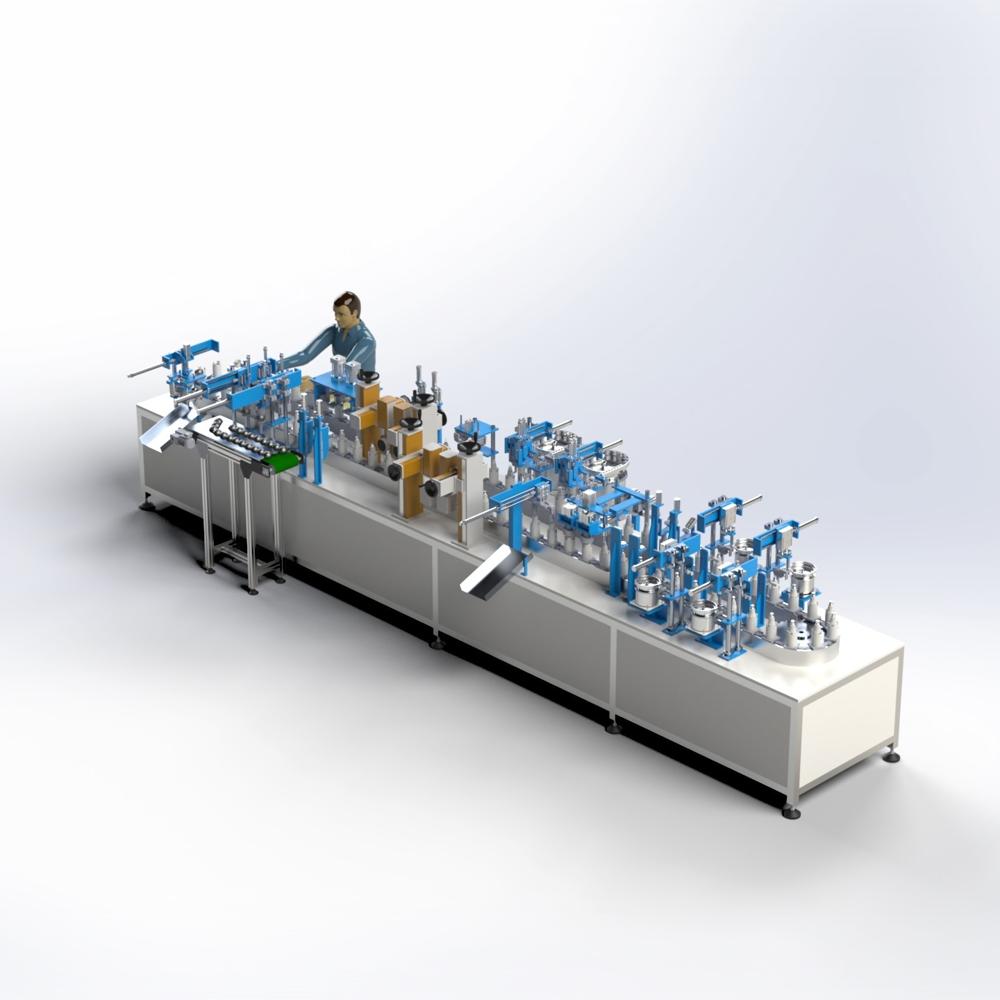

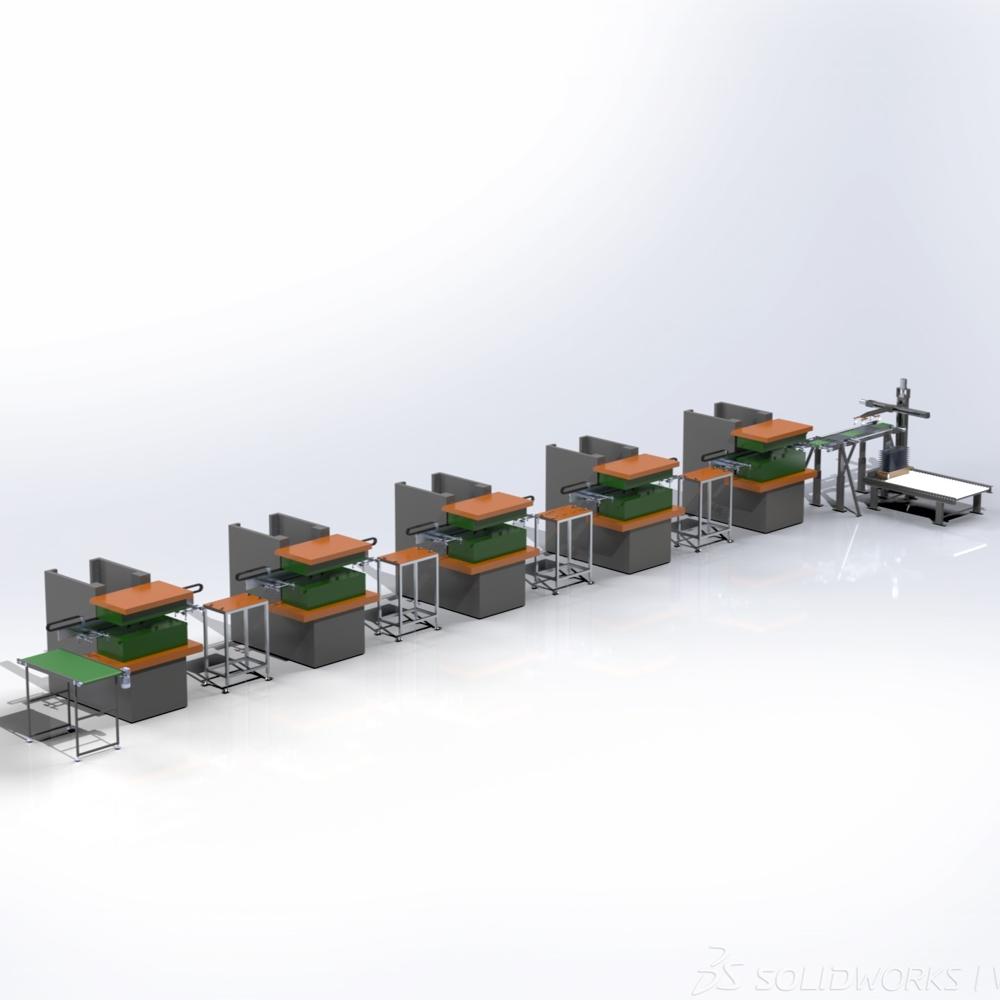

We offer a fully automated Pick and Place System engineered specifically for multi-stage power press operations in the sheet metal industry. This advanced setup automates sheet handling across multiple presses, minimizing manual intervention and maximizing throughput.

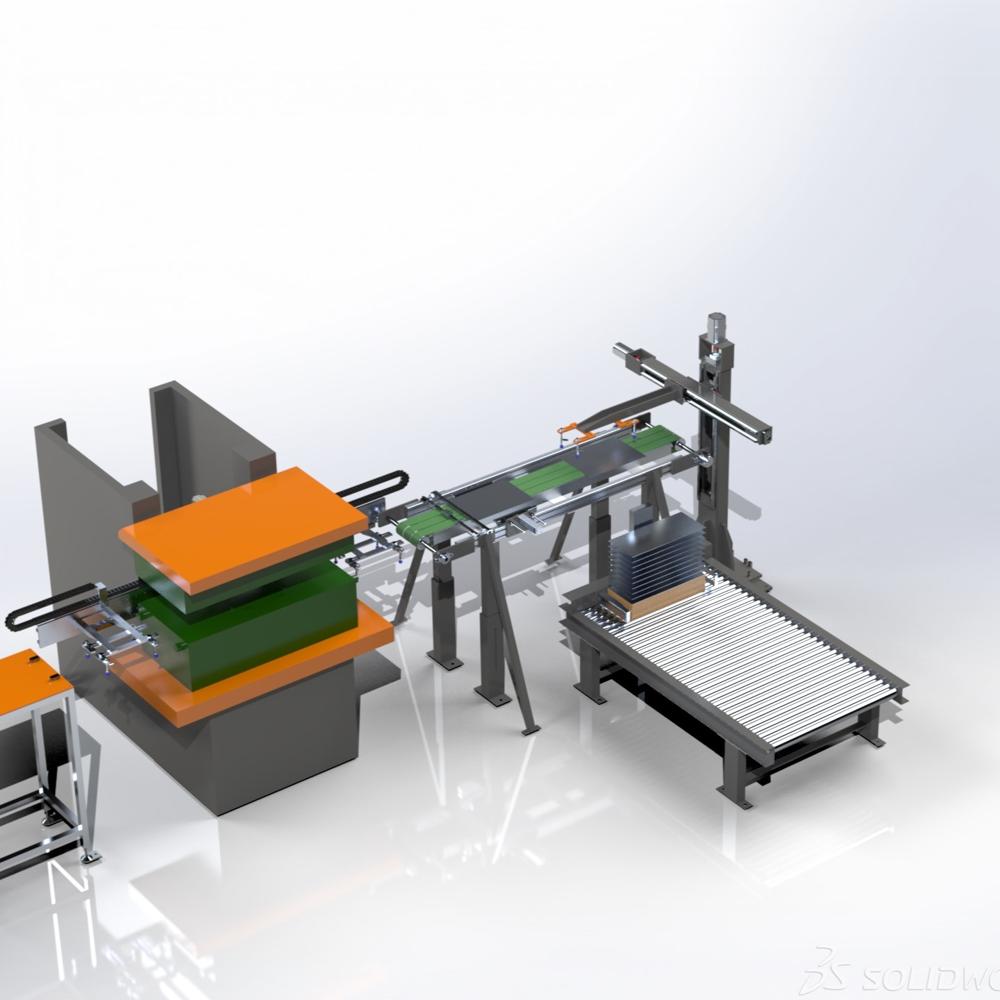

Designed with servo-driven precision, the system handles sheet placement from pallet loading to final part ejection onto a conveyor, synchronizing seamlessly across five press machines with intermediate stations.

Key Features:-

Servo-Based Pick and Place Arms for Accurate Sheet Handling

-

Twin-End Vacuum Arm with Dual Functionality

-

Automatic Sheet Separation from Pallet Stack

-

PLC + HMI Controlled for Complete Line Synchronization

-

Seamless Transfer Between 5 Presses

-

End-of-Line Conveyor for Final Part Collection

-

Press-Mounted Arm with Precision-Driven Guide System

-

High-Speed Cycle Time with Repeatable Accuracy

-

Low Operator Dependency & High Safety Compliance

-

Sheet Loading: Operator loads a stack of raw sheets onto the pallet station.

-

Auto Separation & Pick: System adjusts and automatically picks one sheet at a time.

-

Die Feeding: The press-mounted vacuum arm picks the sheet and inserts it into the die.

-

Intermediate Transfer: The dual-ended arm transfers the next sheet to a side table for queuing.

-

Sequential Pressing: Sheets move through 5 presses with automated coordination.

-

Final Ejection: After the last press, the finished part is placed onto a conveyor.

-

Part Collection: Operator collects the completed sheet metal component from the conveyor end.

Customization Available

Fully Automatic Operation

Servo + PLC + HMI Integrated

Made in India

After-Sales Support Provided

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LED Bulb Assembly Machine Category

LED Bulb Assembly Machine

Price 1200000.0 INR / Number

Minimum Order Quantity : 1 Number

Type : Other

Automatic : No

General Use : LED Bulb Assembly

Weight (kg) : 700 Kilograms (kg)

|

M/S K.T.MECHANICAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry